CUSTOMER PROFILE: JOHNSON MACHINE WORKS, INC.

Bulkhead and embed frame (left) and

bulkhead and trash rack (right),

Bulkhead and embed frame (left) and

bulkhead and trash rack (right), part of the Big Creek Lake Diversion Dam gate replacement.

Chariton, Iowa-based Johnson Machine Works, Inc.'s portfolio includes not only structural steel fabrication for commercial buildings, but heavy fabrication projects as well. Those projects typically consist of fabrication with tight tolerances, machined surfaces and machined components.

The company's work on the Saylorville Lake/Big Creek Diversion project highlights some of these specialties, and showcases the flexibility of SDS/2.

The $9.3 million project involves replacement of the slide gate structure at Big Creek Lake Diversion Dam, which has been inoperable since 1998. The dam gate is one of several flood-control structures that protect Polk City, Iowa, residents during high water events.

Although some of the machined components are not what the software was designed to do, Johnson Machine Works' Jason Unger points out that, "the capabilities available to the SDS/2 user with features such as turned solid element and material fuse have proven to be very valuable in creating axles, shafts, bushings, wheels and other turned features with chamfered edges."

To learn more about Johnson Machine Works, visit their website.

If you'd like to see your company or project featured in future issues of The Connector, please send a project description and images to Michele Arnett.

TECH TIP: STABILIZER PLATES IN SDS/2

Figure 1

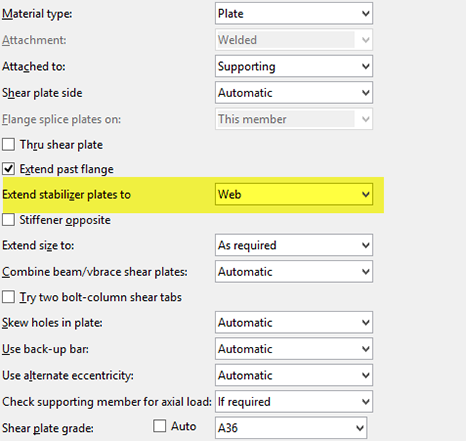

Figure 1According to the AISC 14th Edition Manual, stabilizer plates in an extended shear plate configuration are not required when the required shear strength is equal to or less than the available strength to resist lateral displacement. (Please refer to the Requirement for Stabilizer Plates section found in the AISC 14th Edition Manual on Page 10-105 for more information on these requirements.)

When designing connections using either the ASD 14 or LRFD 14 design methods, SDS/2 takes these AISC requirements for stabilizer plates into consideration to determine if they should be provided or not. You can choose to ignore these requirements and always provide stabilizer plates by turning on the option Always provide stabilizer plates, found in Job or Fabricator Options, as shown in Figure 1.

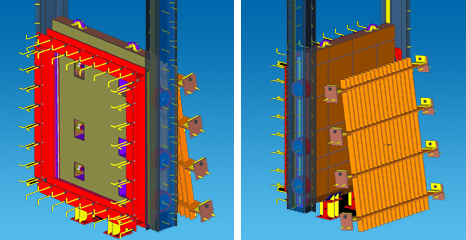

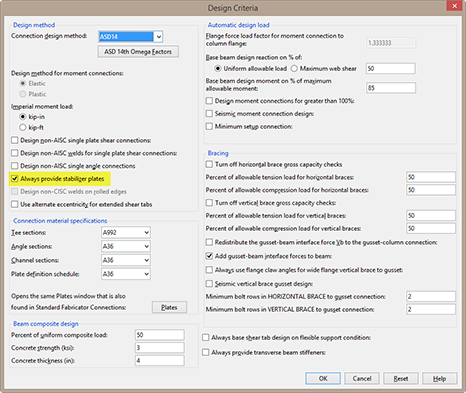

When stabilizer plates are provided, if half the column flange minus k1 distance is less than 4 inches, the stabilizer plates extend to the column web. Otherwise, they extend from the k1 distance to the toe of the flange. In SDS/2 2015, you can force the stabilizer plates to extend to the column web by setting the option Extend stabilizer plates to Web, found in Connection specifications, as shown in Figure 2.

SIGN UP TODAY FOR ONLINE TRAINING

Design Data now offers an online basic training course so you can attend from the comfort of your own office, with less downtime and no travel expenses. This basic training course covers project setup, member input, connection design, material input and more. The course will consist of live training and Q&A sessions with a certified SDS/2 instructor, video training, and application exercises for a hands-on experience. It will take an estimated 30 hours to complete the course, depending on skill level and learning ability. The cost for the four-day online basic training course is $500 per person.

Learn More and Register

To learn more about online training, including training dates and the course schedule, click here. Please note that you must have a login to access this page. If you don't have a login, contact your support representative.

REGISTRATION OPEN FOR 2016 NASCC

Registration is now open for the 2016 NASCC: The Steel Conference, taking place in Orlando, Florida, April 13-15.

NASCC is the perfect place for steel fabricators, detailer, erectors and structural engineers to interact with their peers and learn more about structural steel design and construction. This year’s conference includes more than 100 technical sessions and an extensive trade show with nearly 200 exhibitors. Design Data will be exhibiting in booth #801.

To register for NASCC or to view the advance program, complete with a detailed list of the conference sessions, click here.